My C02 module is designed to trace DCC Railcom traffic for decoder debugging and development purposes. In particular the Railcom capture is an important feature and helps to validate if a decoders is RCN-217 compliant. The C02 uses the Vt100 terminal emulation control codes for its user interface. Therefore a VT100 capeable terminal program is a must (e.g. putty, teraterm). The USB interface is galvanically isolated from the DCC track potential.

User Guides

- User Guide - DE

- User Guide - EN

My current PCB layout uses SMD footprints with 0.5mm pitch and mostly 0603 but some 0402 parts. Reflow soldering is my recommendation, but with some experience handsoldering may also be possible.

- 4-layer PCB, FR4, 1.6mm

- CPU: mega328pb

- USB: FT232x (Mini-B)

- DC/DC: NME0505SC (or compatible)

Filename structure: { pcb }{ code }{ version }.hex

Example: C02F0001.hex

| Description | |

|---|---|

| pcb | Name of matching hardware (C02) |

| code | Type of code contained (R=rom, B=bootloader, F=flash, U=bld update, P=UPDI/SPI factory code) |

| version | Release version (####) |

The fuse settings as well as the P-code (C02Pxxxx.hex) has to be installed by using the ISP.

Details

CAUTION: Before connecting the ISP, the jumper next to the ISP 6-pin interface must be closed (yellow jumper on picture).

| Fuses Setting | Bootloader Install |

|---|---|

|

|

Subsequent main code updates can be done via uploading the new firmware (C02Fxxxx.hex) file to the bootloader console prompt.

Details

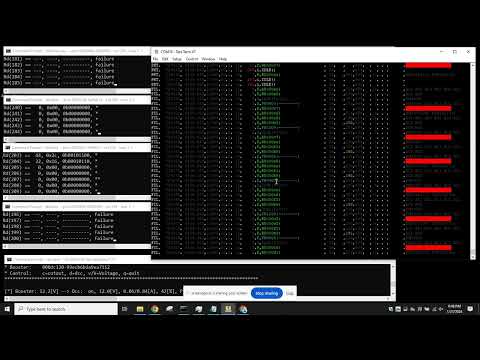

Operating the C02 is within the terminal window.

Below some example screens of the different functional sections. The screens (called aspects) can be switched by pressing F1-F7. All screens are updated in real-time speed, ensuring always up-to-date information shown.

| Aspect | Example |

|---|---|

| F1: Console prompt. |  |

| F2: DCC/Railcom line by line real-time trace. |  |

| F3: DCC/Railcom decoder payload |  |

| F4: DCC/Railcom timing |

|

| F5: DCC command set |  |

| F6: Railcom response set |  |